cnc router table for metal

The application of cnc router table for metal machine is very widely.

It can process metals and non-metals and other composite materials.such as aluminum, copper, marble, artificial stone, gypsum, wood, acrylic, etc.

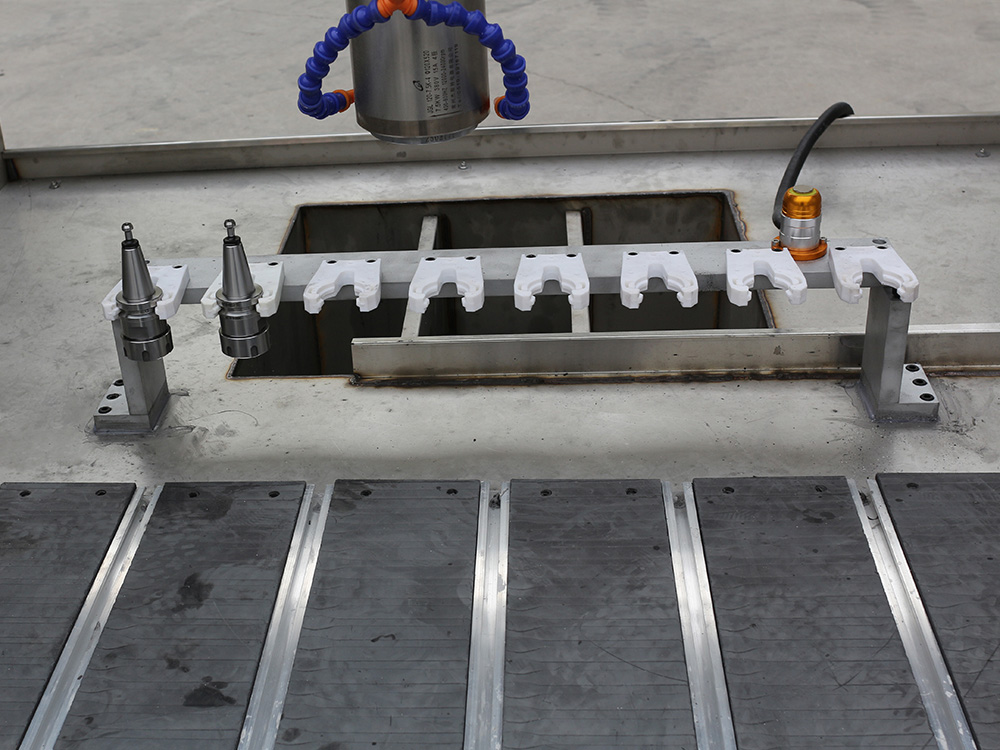

Three axes are ball screws drive , the spindle can automatic change tools.

The machine with fast processing speed and high precision.

Main Features

▶ 6MM steel pipe welded frame, multi support structure, stable structure without deformation.

▶ The gantry frame is reinforced with steel plates , reduce vibration during operation and achieve high accuracy.

▶ The cnc router table for metal machine adopts servo motors.,which have fast working speed and high accuracy.

▶ The Taiwan LNC control system operates stably and automatically processes input paths.

▶ The three-axis adopts HIWIN guide rail and TBI ball screw transmission, with high machining accuracy.

▶ 5.5KW special water-cooled spindle, the spindle can automatically replace cutting tools. Reduce manual labor, and have fast processing speed.

▶ The machine is dustproof and waterproof, extending its service life.

Main Parameters

● Working area :1000mmx2000mmx300mm.

● XYZ travel positioning accuracy: ≤0.01mm.

● XYZ repositioning positioning accury: ≤0.025mm.

● Drive system X-Y -Z axis: TBI ball screw.

● Spindle: 5.5KW water-cooled spindle,atc change tools.

● Tools: 8 tools.

● Spindle speed: 0 – 24,000 RPM.

● Collet type: ER20.

● Max velocity: 25m/min.

● Max working speed: 10m/min.

● Work mode: Servo motor.

● Working voltage: AC220V/380V.

● System: LNC control system(optional SYNTEC system).

● Net / Gross weight: 1400kg / 1600kg.

● Optional parts: rotary axis, SYNTEC cnc system, Yaskawa servo motor.

Product Picture

Operation and usage

• Easy to operate: The control system is easy to learn and users can quickly get started, including writing, editing, and executing machining programs.

•Automated work: automatic tool changing, automatic tool alignment, and automatic lubrication, reducing manual intervention and improving processing efficiency and accuracy.

•Good safety: limit switches and emergency stop buttons to ensure the safety of operators and equipment.

Application

Cnc router table for metal machine is high-precision CNC equipment,mainly use cutting and carving hard materials such as metal, stone, composite materials, etc. Compared to other CNC routers, it has stronger power and higher precision.

Process metal (aluminum, copper, brass, soft steel), stone (marble, granite, artificial stone), other hard materials (wood,acrylic, hard plastic), etc.

It can be used for processing metal precision parts, nameplates, heat sinks, tombstones, decorative reliefs, artistic decorative pieces, etc.

Company Profile

Our company found in 2011, mainly producing and selling CNC router, laser machine, vibration knives, various furniture manufacturing equipment, etc. After 14 years hard work, we have more than ten long-term partners around the world, and our products are sold to more than 80 countries and cities around the world. Customers have good feedback on our products.

FAQ

Q: Do you accept OEM/ODM?

A: Yes, we can make the machine according to your special requirements.

Q: What is your minimum order quantity?

A: Our minimum order quantity is 1 set.

Q: Can I be your agent in our country?

A: Yes, please contact us for details.

Q: When is your delivery time?

A: Our delivery time for loading one container is 20 days.

Q: Do you have good after-sales service?

A: Yes, our after-sales service is 24*7

Q: I also purchased other goods from other suppliers, can you help me ship them together?

A: Yes, we are very happy to help.