4 Axis cnc stone router

Products Description

Performance Parameter

|

NO.

|

Description

|

Parameter

|

|

1

|

X,Y,Z Working Area

|

1500x3000x(300-700mm)*±180°

|

|

2

|

Table Size

|

1800×3500mm

|

|

3

|

X,Y,Z Traveling Positioning Accuracy

|

±0.02/300mm

|

|

4

|

X,Y,Z Repositioning Accuracy:

|

±0.02mm

|

|

5

|

Table Surface

|

T slot table(optional vacuum table)

|

|

6

|

Frame

|

Big Steel Tube Structure

|

|

7

|

X, Y Structure

|

Helical rack gear , HIWIN Linear guide

|

|

8

|

Z Structure

|

Imported Ball Screw , HIWIN Linear guide

|

|

9

|

Max. Power Consumption

|

(Without Spindle) 4.2Kw

|

|

10

|

Max. Rapid Travel Rate

|

50000mm/min

|

|

11

|

Max. Working Speed

|

25000mm/min

|

|

12

|

Spindle Power

|

5.5kw/9kw

|

|

13

|

Spindle Speed

|

0-24000RPM

|

|

14

|

Drive Motors

|

Stepper motor(Optional servo motor)

|

|

15

|

Working Voltage

|

AC380V/50/60Hz,3PH (Option: 220V)

|

|

16

|

Command Language

|

G Code

|

|

17

|

Operating System

|

DSP A18/Stntec

|

|

18

|

Computer Interface

|

USB

|

|

19

|

Flash Memory

|

512M

|

|

20

|

Collet

|

ER25

|

|

21

|

X,Y Resolution

|

<0.02mm

|

|

22

|

Software Compatibility

|

UG , Power mill

|

|

23

|

Running Environment Temperature

|

0 – 45 Centigrade

|

|

24

|

Relative Humidity

|

30% – 75%

|

|

25

|

Packing Size

|

4.1*2.3*2.6m

|

|

26

|

N.W.

|

1600KG

|

|

27

|

G.W.

|

1800KG

|

|

28

|

Optional Parts

|

Dust Collector/ Dust Hoods for three Axis

|

|

Vacuum Pump

|

||

|

Rotary System

|

||

|

Mist-cooling System

|

||

|

SIEMENS/DELTA/ Panasonic Servo Motors

|

||

|

Colombo Spindle

|

||

|

X:2m, Y:4m, Z:1m

|

Main Parts

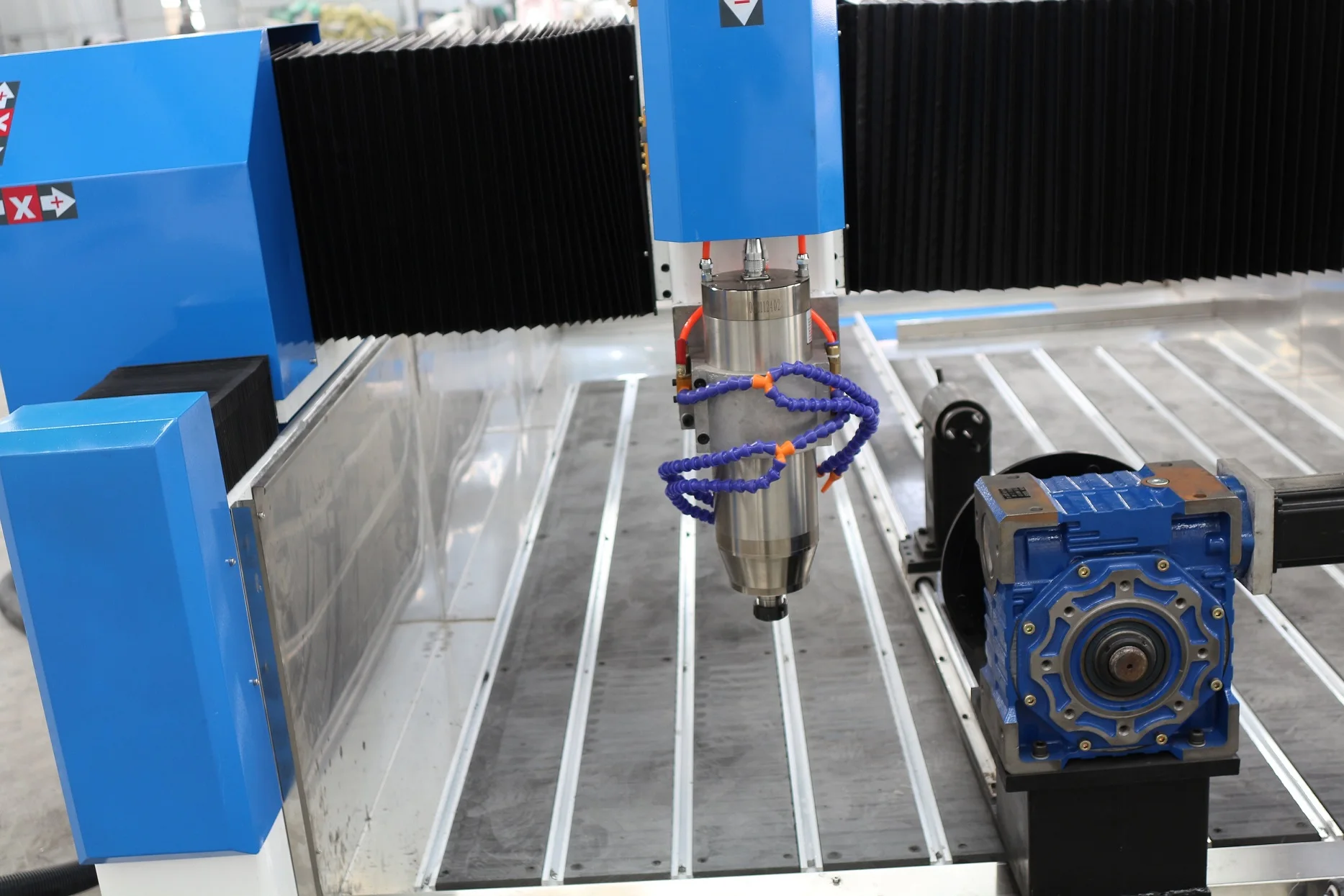

The stone cnc router machine used water cooling spindle.

and the cnc engrave machine with high precision and long

life time.steady working,easy to start.

The cnc router machine of stone is equipped with a rotary

axis, which can easily carve 4D artworks.Roman columns

are the most common.

duty steel pipes, and the steel pipes on the bed have a high

density. Tempering treatment of the frame, which will not

deform after long-term application

other parts

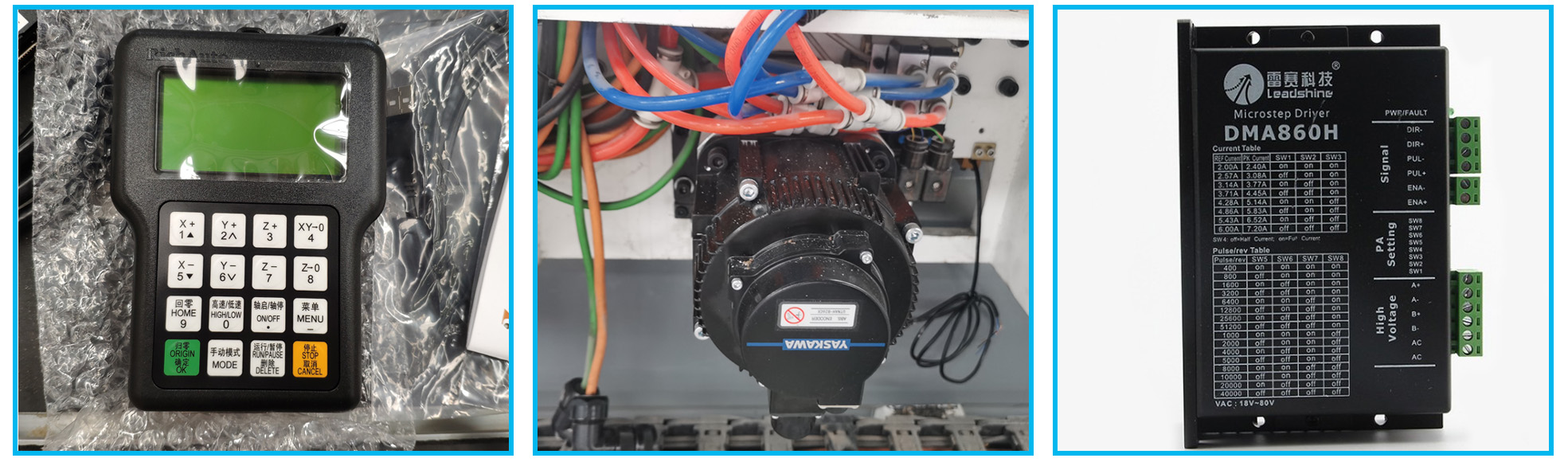

THE DSP THE SERVO MOTOR THE DRIVER

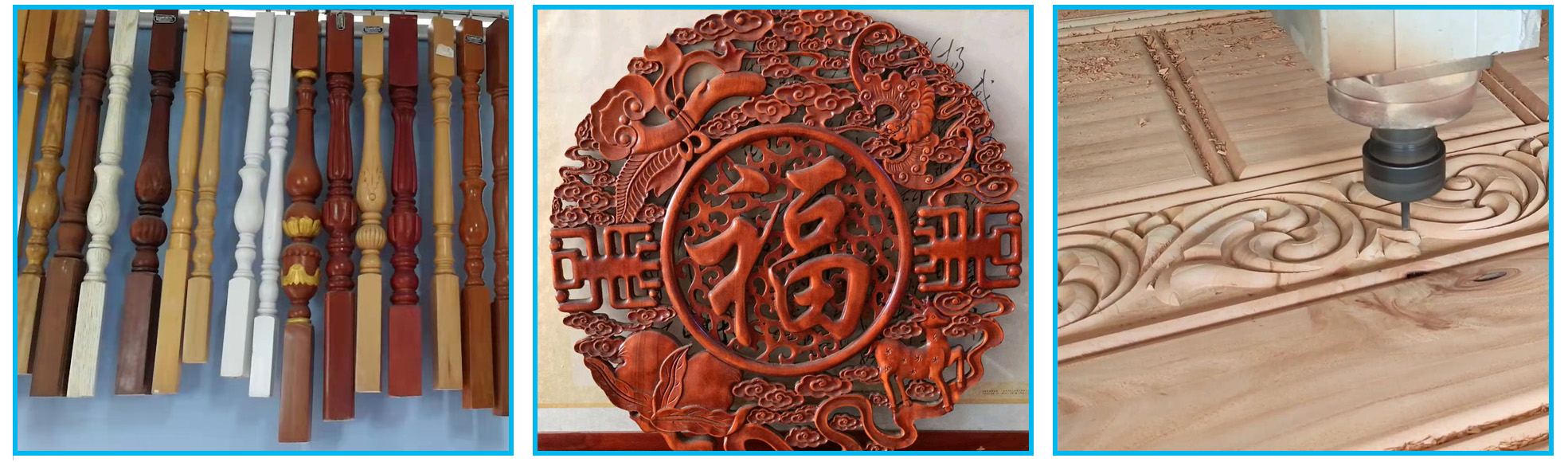

Working Samples

WOODEN ROMAN COLUMNS HOLLOW CARVING CARVING DOOR AND FURNITURE

FAQ

Please tell the material you want to working on ?

How to working on it ? Engraving ? Cutting ? Or other ?

What’s the MAX size of these material ?( length ? Width ? Thickness ?)

The payment is 30% or 50% T/T or Alibaba trade assurance in advance, balance after machine finished.

The proucing time is about 10-20 days depend on different machines.

Yes,we will ,if you come to China,we will offer you free training until you can use machine freely.And if

you are busy ,we will have the special engineer to your country,but you need to bear some fee,like

tickets and hotel and meal.

we offer you 24 hours service phone,skype or whatsapp, our engineer also can go to door install or training.

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to

make sure they can work very well before being out of factory.

The testing video and pictures will be available before delivery.