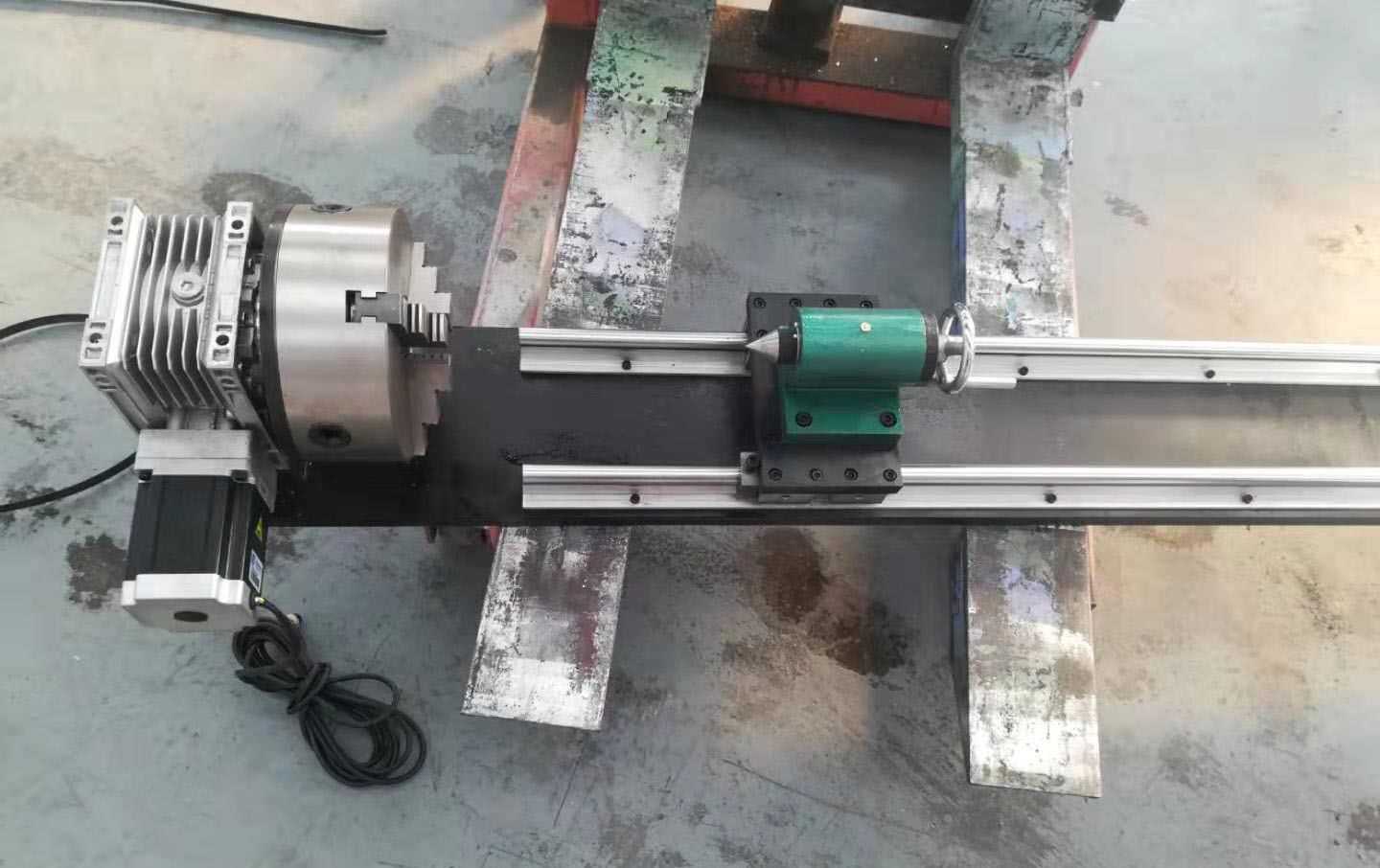

4 Axis Cnc Wood Cutting Machine

Four-axis structure:

4 Axis Cnc Wood Cutting Machine is adding a rotating axis to regular CNC engraving machine to achieve cylindrical engraving. Suitable for cylindrical or three-dimensional carving in industries such as woodworking, advertising, and metal. Flat cylinders can be carved, with one machine serving two purposes.

Advantage:

The advantage of the 1325 woodworking machine is not only that it can perform complex carving operations. This machine also has the following advantages:

1. Efficiency: The 4 Axis Cnc Wood Cutting Machine can quickly complete a large number of cutting and engraving tasks, thereby reducing production time and cost.

2. Precision: The machine’s precise positioning and high-speed operation means make it possible to precisely develop the design engraving workpiece that matches the requirements.

3. Diversity: The 1325 woodworking machine is suitable for many different types of wood and other types of materials. This provides a variety of woodworking and carving design options.

4. Flexibility: The 4 Axis Cnc Wood Cutting Machine can engrave the 3d product and through the side rotation axis can Cylindrical carving .

|

Description

|

Parameter

|

||

|

XYZ working area

|

1300*2500*200mm

|

1500*3000*200mm

|

2000*3000*200mm

|

|

Table size

|

1310*3000mm

|

1510*3500mm

|

2010*3500mm

|

|

XYZ travel positioning accuracy

|

±0.02mm

|

||

|

XYZ repositioning

positioning accury

|

±0.025mm

|

||

|

Table surface

|

Bakelite sheet

|

||

|

Grantry

|

Steel

|

||

|

Drive system X-Y axis

|

Rack actuation

|

||

|

Drive system Z axis

|

Ball screw

|

||

|

Spindle power

|

3.2/5.5KW

|

||

|

Max velocity

|

50m/min

|

||

|

Max working speed

|

25m/min

|

||

|

Spindle speed

|

0-24000rmp

|

||

|

Work mode

|

Step(optional servo)

|

||

|

Working voltage

|

AC220V/380V

|

||

|

Command language

|

G code

|

||

|

Interface

|

USB or parallel port

|

||

|

Operating system

|

Ncstudio/DSP/Mach3

|

||

|

Flash memory

|

128

|

||

|

X-Y resolution

|

0.025mm

|

||

|

Software environment

|

Wentai type3 artcam

|

||

|

Running environment

|

Temperature:0-45°C

|

||

|

Paking size

|

3300*1900*1900mm

|

||

|

Net weight

|

1000 kg

|

||

|

Gross weight

|

1200 kg

|

||

3、Aluminum profile workbench, PVC flat surface, can protect and improve the service life of the machine。

4、X-Y -Z axes adopt Taiwan linear linear linear guide rails。

In the handicraft industry, the 1325 woodworking CNC carving machine can be used to carve products, such as seals, business cards, signs, and so on. It can accurately depict details and create perfect products.

In the construction and decoration industry, the 1325 woodworking CNC carving machine can be used to carve decorative materials ,such as walls and ceilings. It can create various patterns and patterns, making the decorative effect more unique.

Please tell the material you want to work on.

How to working on it? Engraving, Cutting Or other?

What’s the MAX size of these material? ( length? Width? Thickness?)

The payment is 30% or 50% T/T or Alibaba trade assurance in advance, balance after machine finished.Q3. What is the producing time after order?

The proucing time is about 10-20 days depend on different machines.Q4. If we don’t know how to use the machine,can you teach us?

Yes, we will, if you come to China, we will offer you free training until you can use machine freely. And

tickets and hotel and meal.Q5. How about your after-sales service?

We offer you 24 hours service phone, whatsapp or E-mail, our engineer also can go to door install or training.Q6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The

The testing video and pictures will be available before delivery.