large wood cnc router 2130

Large wood cnc router 2130 mainly use process large materials.

The machine uses 3.2kw high-power water-cooled spindle, which has strong cutting force and fast processing speed.

It can process large MDF, plywood, plastic sheets, aluminum plates etc.

Main Features

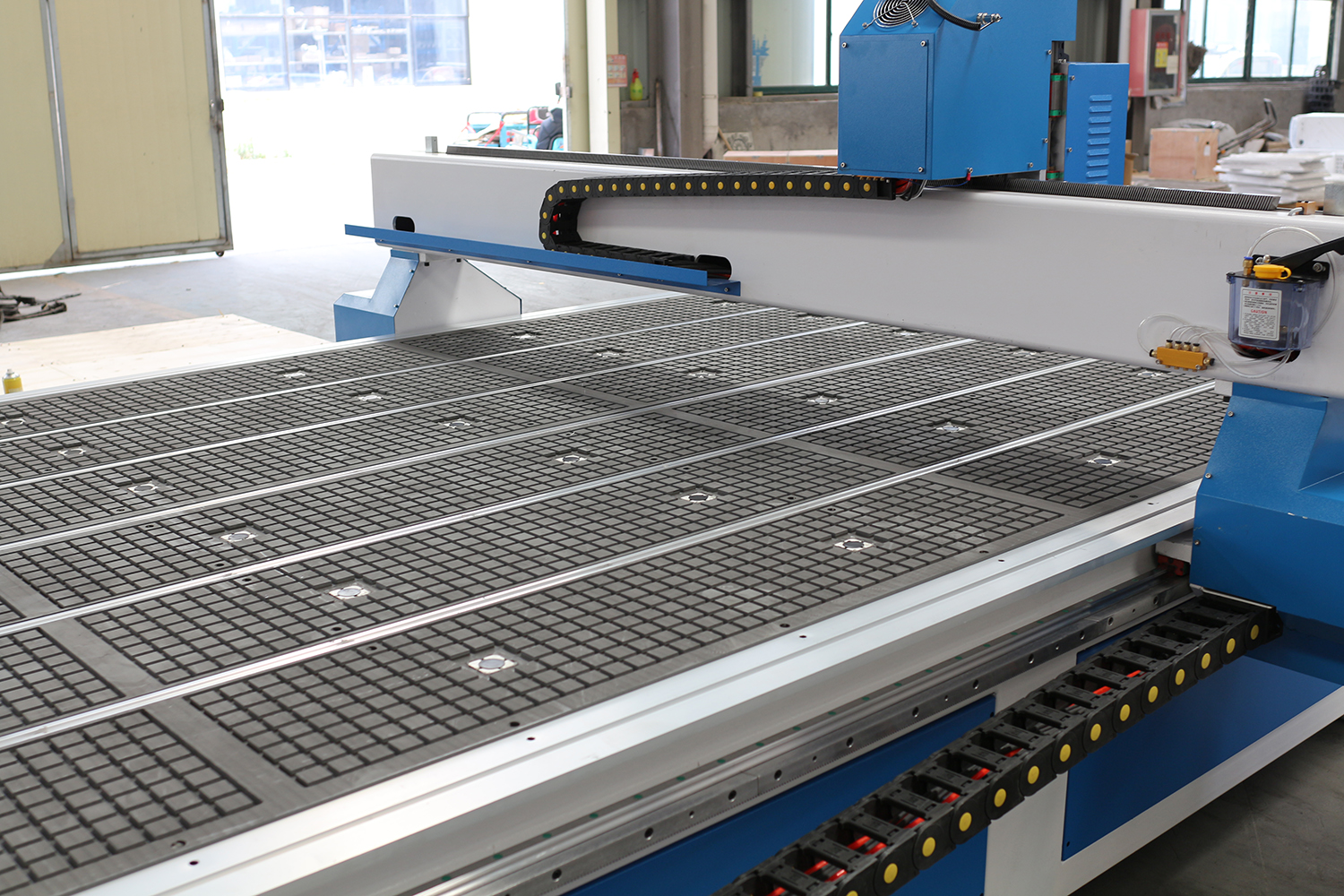

♥ Steel pipe welding frame, with multiple supports in the middle, stable structure.

♥ 3.2KW high-power water-cooled spindle, strong cutting force and fast speed.

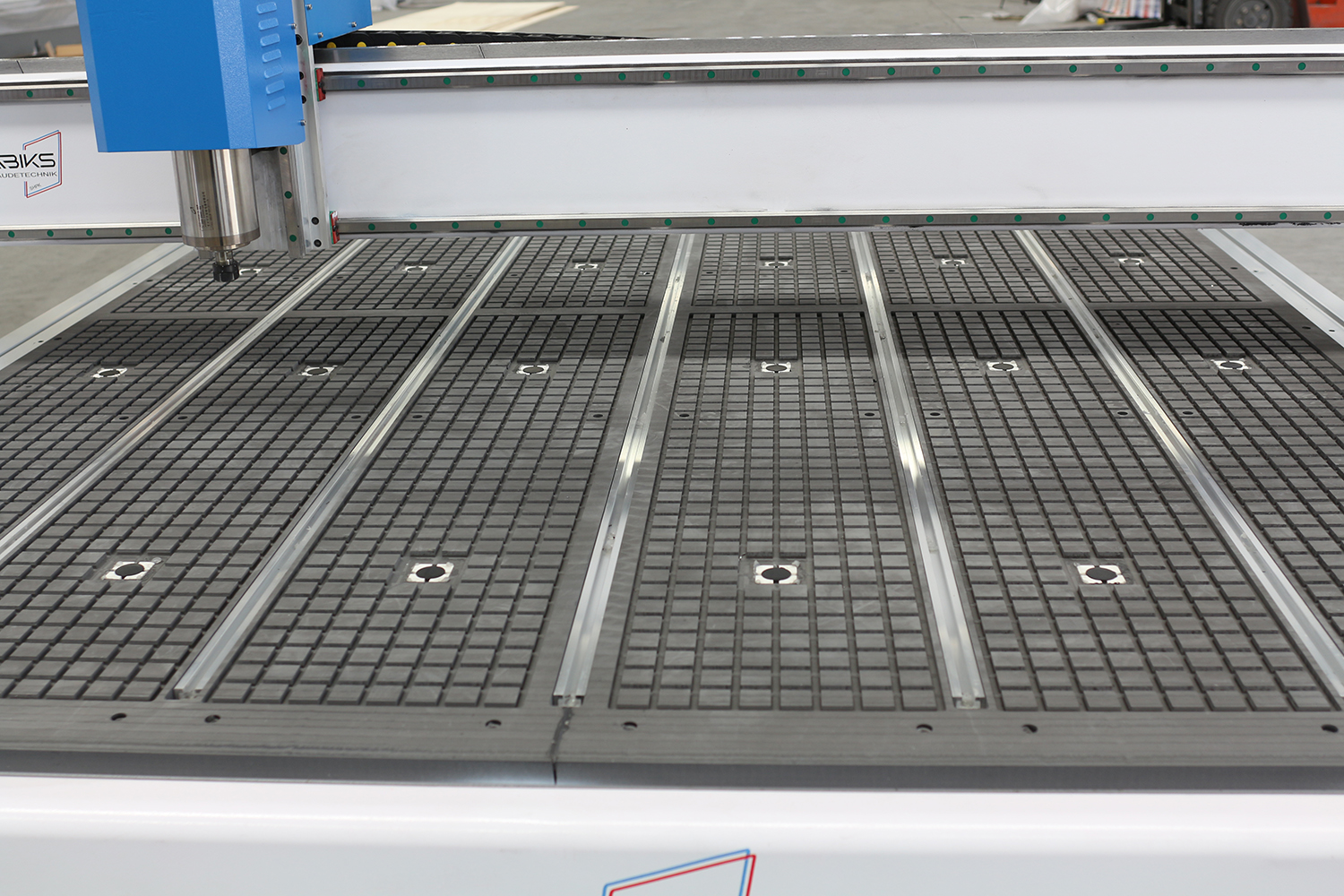

♥ Vacuum work table, different areas independent control, can better fix materials.

♥ The Y-axis is controlled by two stepper motors, with fast processing speed.

♥ The three axes use HIWIN square guide rails ,ensure the machine stable.

♥ The Z-axis uses TBI ball screw drive , improve processing accuracy.

♥ Limit Switches on all Axes

♥ Weihong control system, computer operation, simple and convenient.

♥ The Large wood cnc router 2130 can cut and engrave (flat engraving, relief) almost all materials

Main parameters

Model: cnc router machine 2130

Working area: 2100x3000mm

Machine Bed Width/Length: 2250X3550mm

Z Travel: 200mm

Table:Vacuum table

Positioning: 0.01mm

Repositioning: 0.025mm

Frame:Steel tube welded frame

Max velocity: 50m/min

Max working speed: 25m/min

Spindle power: 3.2KW

Max Speed: 24000RPM

Cooling System:Water cooled spindle

Inverter:BEST

Motor: Stepper motor

Transmission: X and Y axis – Guide rail rack Drive, Z axis-TBI Ball Screw Drive

Operating system: Weihong control system

Interface: USB and Network

Power: AC 220V/380V,Single/Three phase

Packing size: 3600*2250*1850mm

Net Weight/Gross Weight: 1600kg /1800kg

Optional accessories: Rotary axis, 5.5KW water cooled spindle, Air cooled spindle,Servo motor,SYNTEC control system.

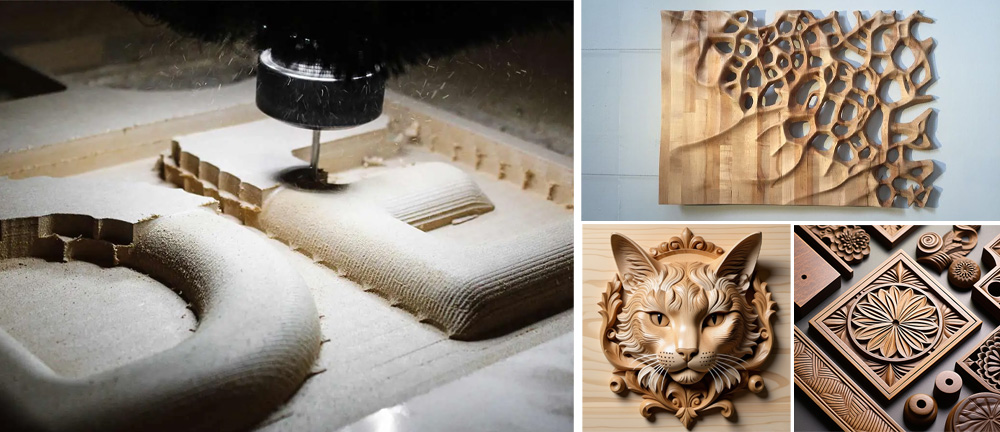

Application

The Large wood cnc router 2130 has many applications and can process almost all materials.such as wood, plywood,PVC, aluminum board, acrylic, ABS, marble, granite, metals, hard plastics, etc.

Advertising industry: various billboards, various signs, various logos, trademarks, fonts, etc.

Woodworking industry: cutting and cutting various furniture, home decoration, wooden crafts, art models, and other wood products.

Mold industry: carve various molds, wooden molds, aviation wooden molds, architectural models, automotive foam molds, etc.

Samples

Product pictures

Company Profile

Our factory was established in 2011, mainly producing and selling CNC router, laser engraving and cutting machines, vibration knives and other CNC equipment. Our products use high-quality accessories, the assembly process is very strict, and each machine must be tested. Customers have good feedback on our machines. Our products are sold to more than 80 countries and cities around the world.

FAQ

Q1.How to get the most suitable machine and best price

Please tell the material you want to working on ? How to working on it ? Engraving ? Cutting ? Or other ? What’s the MAX size of these material ?( length ? Width ? Thickness ?)